Case Study: Ecobat Robosaw project

Ecobat is a world leader in the production of lead, lead alloys, and the recycling of lead batteries. Their vast network features 11 smelters across two continents with an average annual output of 840,000 tons of lead. Production is matched by a lead recycling system which allows them to recover and repurpose over 99% of the metal.

Ecobat Resources at Welwyn Garden City are the UK’s leading manufacturer of rolled lead sheet, with a reputation for outstanding product quality and produce everything from recycled lead.

The Requirement

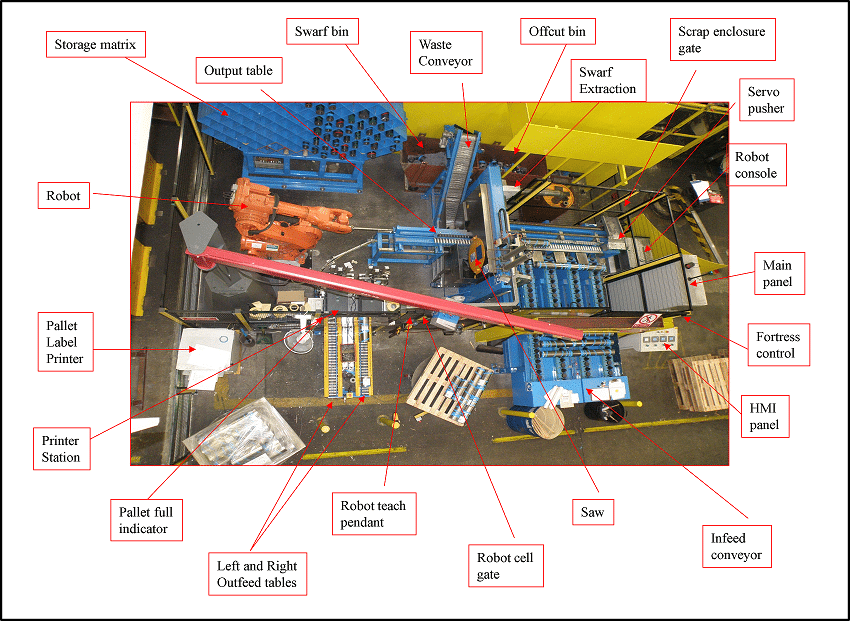

Ecobat utilised two robotic saws in their manufacturing facility, which were fully automated to cut lead sheets to bespoke sizes according to customer orders. They allowed the entire process to be fully automated, from order placement through to the printing of the shipping label. Ecobat had initially had a program written in Visual Basic to integrate the saws with the System 21 ERP, enabling order dimensions to automatically be sent through to the two saws, with workflow processes in place to recognise any errors in dimensions and prevent errors and minimise waste.

The Solution

As the business migrated away from System 21 to SAP, the IMS team had to re-write the |Visual Basic program to integrate with the new ERP to maintain the same automated functions as they had previously utilised, in order to save time and the need for human resources. The IMS development team brought together their knowledge of Visual Basic, PHP and My SQL development, as well as data management skills, and created a new SAP-compatible program.

The Outcome

The two saws maintain the previous automation levels and Ecobat does not have to hire additional resources to oversee the machines.

“The ERP SAP migration project had very tight deadlines IMS were able to be flexible and complete the project on time. They are committed to providing their customer with the highest quality service.

The IMS team was professional, responsive, and knowledgeable. They were always willing to go the extra mile to ensure the project succeeded.”

Mohsin Malik, Ecobat Resources

Contact the IMS team today for more help and support with your IBM i system improvements.